What should I do if the PCB board is bent? Cause analysis and improvement method of pcb board warping .today author from qihe smt pick and place machine tell you about it with you .

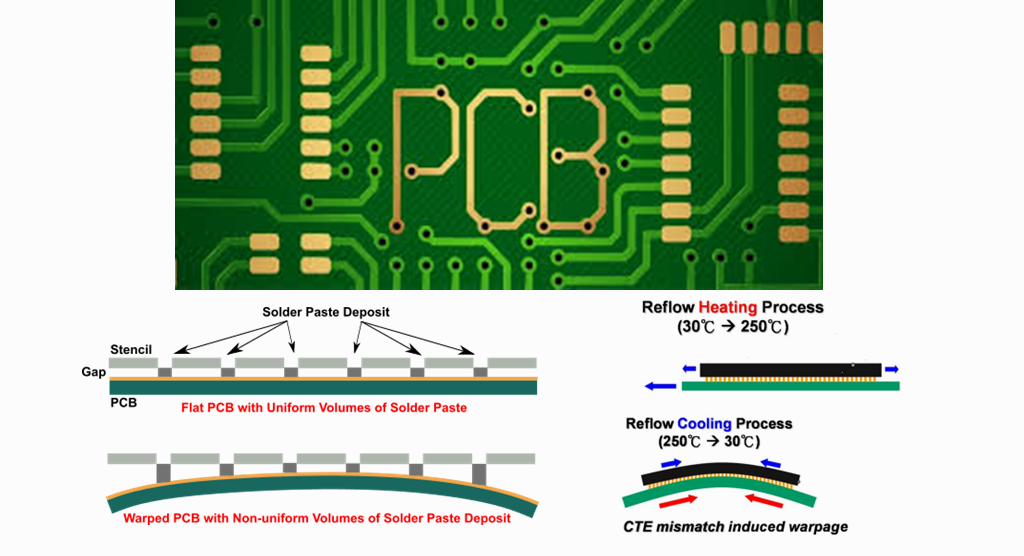

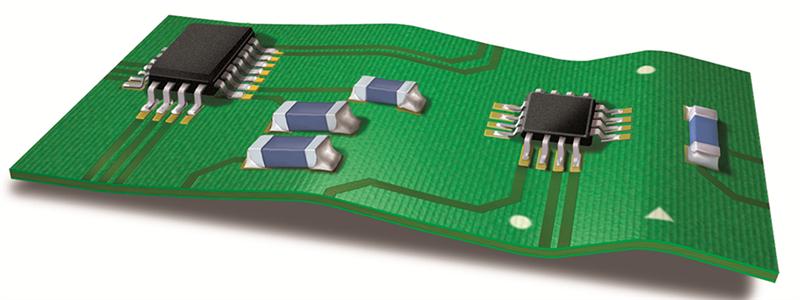

After the SMT pick and place chip machine processing ,many factories will encounter the phenomenon of bending and rocking of the circuit board during reflow soldering. In severe cases, it may cause bad SMT phenomena such as empty welding of electronic components and tombstones. These phenomena are caused by Because of what? It is because of the uneven pressure on the board or the uneven pressure on the board, which leads to the phenomenon of bending or rocking. When the board passes through the high temperature of reflow soldering, the circuit board will become soft, and the thermal expansion and contraction of the circuit board material. The characteristics of chemical factors have resulted in bent plates and rocker plates.

Solutions and methods for bent plates and rocker plates

Reduce the temperature of reflow soldering or adjust the speed of heating and cooling of the board through reflow soldering, reducing the occurrence of board bending and warping

Plates with higher Tg can withstand higher temperatures and increase the ability to withstand pressure deformation caused by high temperature, relatively speaking, the material cost will increase;

Increase the thickness of the board, which is only suitable for products that do not have PCB thickness requirements for the product itself, and thin products can only use other methods;

Reduce the number of panels and reduce the size of the circuit board, because the larger the panel, the larger the size. After the board is heated at high temperature by reflow soldering, the local pressure is different, and it is easily affected by its own weight. It is easy to cause partial depression and deformation in the middle

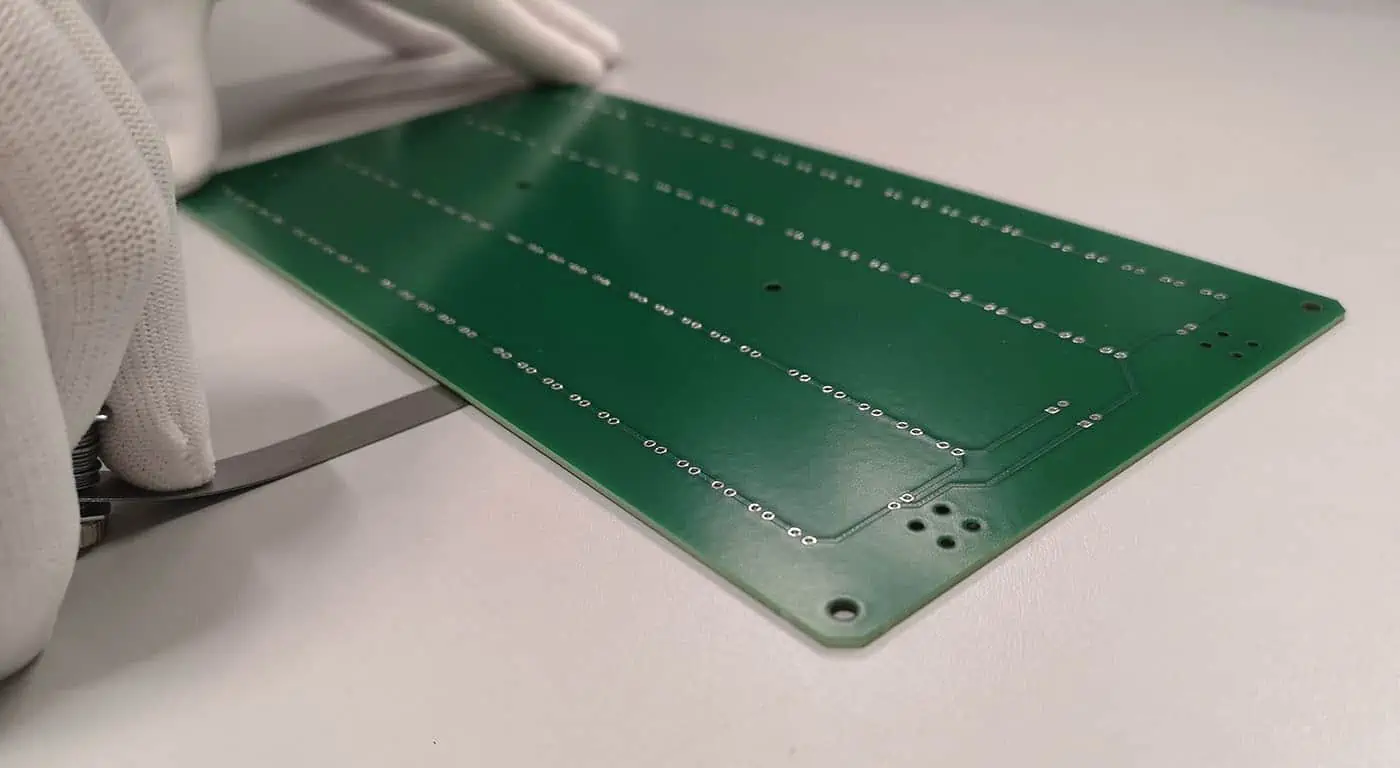

Use the oven tray fixture to reduce the deformation of the circuit board. After the circuit board undergoes high temperature thermal expansion and subsequent cooling and contraction after reflow soldering, the tray fixture can stabilize the circuit board. However, the filter tray fixture is more expensive and requires Add labor to place pallet fixtures

you can also choose which smt pick and place machine meets your need . like qihe tvm802 qm61 series .

-

Professional PCB external pumping type inflatable vacuum packaging machine, moisture-proof and anti-oxidation, guarding the quality of circuit boards

-

Professional PCB external vacuum packaging machine , moisture-proof and anti-oxidation, protecting the quality of circuit boards

-

High – Precision Offline PCBA Cleaner QH-800: Remove Stubborn Flux Residue Completely

-

Intelligent 3D Monorail SPI QS400, powered by AI, automatically identifies and analyzes solder paste printing problems!

-

SPI-QS800 Ultra Precise In line Single Track : Detect Tin Paste Defects with Micron – Level Accuracy

-

Offline 2D AOI, PCB, FPC universal inspection tool, to meet the needs of diversified production

-

Online 2D AOI: Real – Time Precision for Continuous SMT Production

-

QH-VVL360 Rapid 3D Imaging for Lightning – Fast SMT Defect Detection

-

Automatic Screen Printing Machine RSE High Efficiency high Power Printing PCB

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe smt can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.