TVM802BX pnp desktop smt line first start running from Gevorg smt pick and place machine

TVM802 desktop SMT production line Deluxe edition pick and place machine

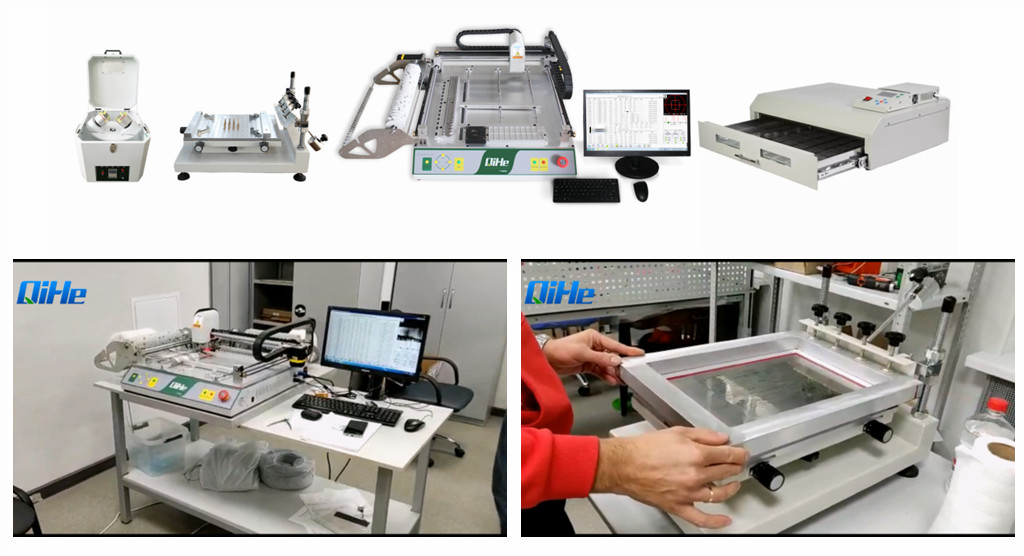

We can provide low volume SMT line for small batch production for the start ups & R &D . 2 head Pick and place machines available. There are two models(29 slots or 46 slots) for you to choose from . Desktop SMT line also including automatic solder paste mixer,manual printer and tabletop reflow oven .Can handling smallest package size:0402 inch and up to largest size:TQFP100.

Device combination configuration

solder mixer QH3502→manual stencil printer QH3040→Desktop PNP machine TVM802BX→ →Desktop reflow oven 962C

SMT Process Step 1

QH3040 high-precision manual stencil printer The same platform as printer can be selectable , easy to locate both single and double sides of PCB board.High flexibility ensure high printing precision.

The steel stencil can be rotated 30 degrees at most , and the precision can be kept all the way when repeat works, can be comparable with automatic machine.

Using the way of steel stencil movement to adjust the best position, combining with the fine adjustment of X-axis Y-axis to correct, convenient and efficient.

SMT Process Step 2

TVM802BX SMT pick and place machine (desktop pnp mounter). The advantages of this model are the built-in industrial control computer, optimized driver and software algorithm,2 placement heads,46 slots.

Can handling smallest package size:0402 inch and up to largest size:TQFP100.The external dimensions of TVM802BX are 940mm*940mm*320mm. Deluxe edition is mainly composed of built-in industrial control computer,working head, dual vision system, operation platform, patented feeding rack,, closed-loop motor drive system, internal vacumm pump,etc. Voltage AC220V or AC110V, power 150W.

SMT Process Step 3

- QR962C desktop SMT Reflow Oven solder welding Mixed Process

- Single-sided mixing process: (Plug-in and surface-mount components are on the A side of the PCB) Incoming material inspection -> Solder paste mixing -> PCB A-side silk-screen solder paste -> Patch -> A-side reflow soldering – > PCB A-side plug-in -> Wave soldering or dip soldering (a small number of plug-ins can be soldered by hand) -> (Cleaning) -> Inspection -> Rework (first post-inserted)

- Double-sided mixing process: (surface mount components on the A side of the PCB, plug-in on the B side of the PCB)

A. Incoming material inspection -> solder paste mixing -> PCB A-side silk screen solder paste -> patch -> reflow soldering -> PCB B-side plug-in -> wave soldering (a small number of plug-ins can be hand soldered) -> (cleaning )-> Inspection -> Rework

B. Incoming material inspection -> PCB A-side silk-screen solder paste -> SMD -> Manual pad on the A side of the PCB pad solder paste -> PCB B-side insert -> Reflow soldering -> (cleaning) – > Inspection -> Rework (surface mount components on the A and B sides of the PCB, plug-in on either or both sides of the PCB) Surface mount components on both sides of the A and B sides of the double-sided PCB by double-sided assembly Reflow soldering, then manual soldering of the two-sided insert

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

-

QR962C Desktop SMT Reflow Oven solder welding

-

QH3040 high-precision manual stencil printer

-

TVM802B SMT pick and place machine 2heads 46slots desktop Pick&Place Machine standard edition

-

TVM802A SMT pick and place machine 2heads 29slots desktop Pick&Place Machine standard edition