Today author from qihe smt pick and place machine sharing you with a customer case story .QM61 Smt pick and place machine an entry level fully-automatic PCB assembly system

PCB module Design and SMT production

from Saudi Arabia

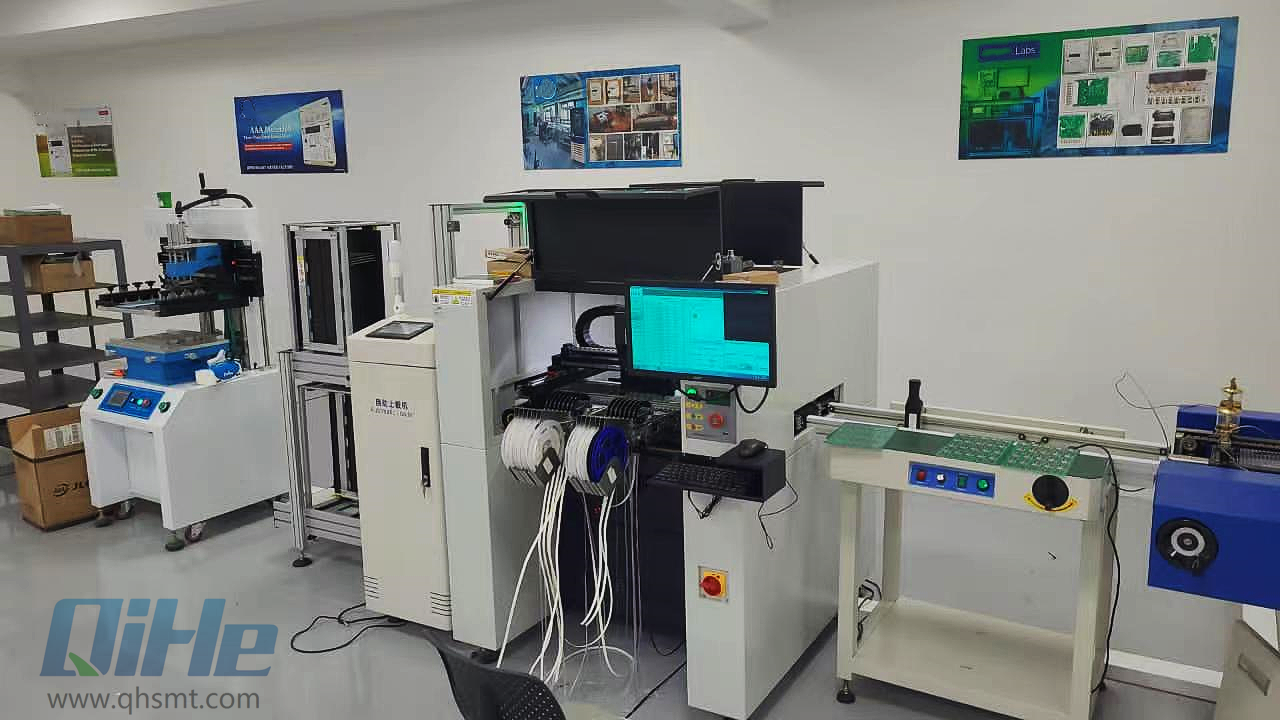

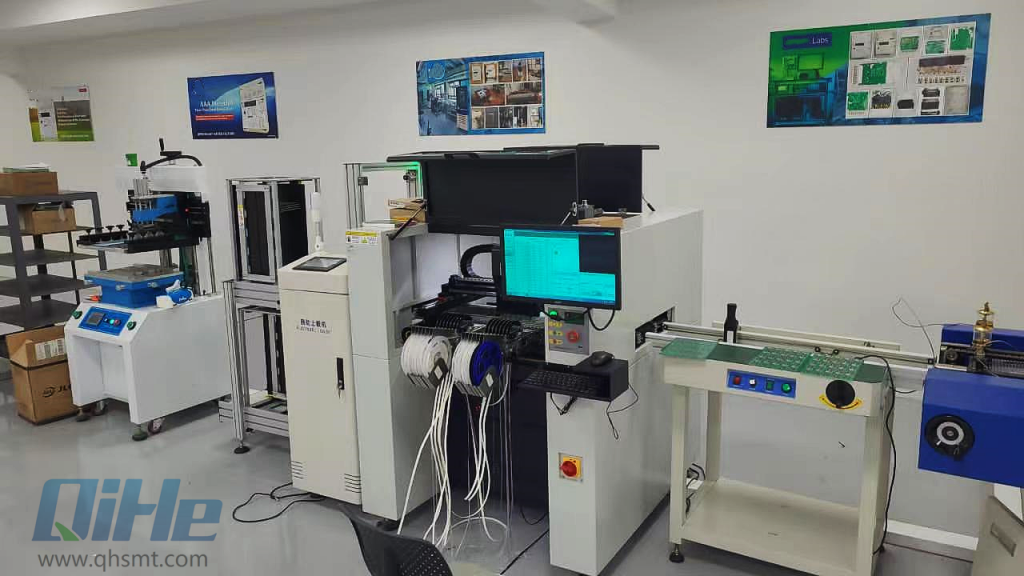

QM61 fully-automatic SMT production line

customer sharing video of QM61 an entry level fully-automatic PCB assembly system from Saudi Arabia

Device combination configuration

solder mixer QH3502→ stencil printer QP3250→PCB uploader QUL350→PNP machine QM61→ conveyor→8 Zone reflow oven QRF835

SMT pick and place machine

The QM61 SMT pick and place machine is designed for mass production or R&D proofing purpose. It contains 6 heads,63 slots .

The hardware including flying shot recognition camera,the Hiwin linear rail,the TBI grinding screw,the master computer ,triple stage transmission rail system.

Upgraded the software functional such as the component library ,the visual surveillance,the safety alerts,the fault previously warning .

QM61 pick&place machine can easily handling special-shaped components, BGA, 0201 inch package.

QM61 chip mounter X Y axis adopts bigger Panasonic servo motor, speed of up to 12000 components per hour (CPH),

The QP3250 high precise sem-automatically solder tin printing machine designed with high-quality speed control motor and linear guide rail and other precision accessories assembled,

so that the scraper head printing smoother.

Double-scrapers printing pressure can be adjusted by the up/down cylinder throttle valve, the lifting speed can adjust effectively avoid resonance.

The printing head can be turned up 45° and fixed lock, convenient scraper loading and unloading and steel mesh cleaning, easy to operate.

The printing head can be fixed after many directions, fixed convenient steel mesh in place, effectively ensuring the printing effect.

The altitude of double-scraper of the printing head can be adjusted by adjusting the nut freely,

so that the force between the scraper and the steel mesh can be controlled.

The level of spacing between the printing table plate and the steel mesh, the adjustment of the scale of the precision spinner, and the scale number display.

benchtop reflow oven

The QRF835 infrared benchtop reflow oven is upgraded from QRF830 model SMT Reflow Oven solder welding .Which increased with adjustable track rail system .

And it uses the PID temperature control system and rapid infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed.

The whole soldering process can be completed automatically and it is very easy to use. It is suitable for the board has chips and output is larger or the welding quality requirements are better.Designed with Multi-temperature curve choose.

Four zones special temperature control mode more stable and precise.High quality thermocouple porcelain bead protect.Full-color HMI human-computer interface(touch screen).

Super anti-temperature fan.Liner hearth use industrial grade anti high temperature and corrosion panel paint.PID microcomputer global temperature control system.

High efficiency and energy saving finned heating tube.High temperature fan.Built in analog governor.

PCB handling machine is commonly called board handling machine or pcb storage machine.A printed circuit board requires gentle handling and optimal storage conditions. This, in turn, promotes higher PCB quality, expands product lifecycle, and maximizes proper functionality as well as performance.

Basically these machines control the flow of “Printed Circuit Boards” (PCB) in an automatic assembly line. Such a line normally consists out of the following machines:pcb uploader QUL350, conveyor,pcb unloaderQDL350.